About Us

Try us once. Trust us always.

KR Diamonds is the North American office for Luc Vets Diamonds, one of the finest diamond manufacturers in the world. The story began simply with two brothers in Belgium over ninety years ago. Our company is passionately committed to carrying out a tradition of expert diamond cutting and service. We are a completely vertical operation and all steps of the cutting process are under our management. Nothing is outsourced. First we carefully select rough diamond crystals from only responsible, documented origins. Then these crystals are sent to one of our five cutting factories where only our product is handled. Upon completion, all polished diamonds make their way back to Antwerp for a final inspection before distribution around the globe.

Our diamonds are the retail professional’s choice and a manufacturer’s trusted partner, prized for their consistent quality. As essential as Ideal cut diamonds are to fine jewelry, for us, it’s still only the beginning. We offer exemplary service, to ensure the success of our clients within the jewelry industry.

We hold all of our clients and their needs in high regard. Since we clearly control all of our production, we can give immediate responses and tailor orders to specific requests with ease. We invite you to take a glimpse into our world including all steps of the process with our skilled teams. Our company and our diamonds are always something of which to be proud.

Ethically Sourced. Conflict Free.

It is important to us that our diamonds are ethically sourced and conflict free. We carefully select and purchase our rough diamond crystals from only responsible, well documented origins. Rest assured our diamonds have not financed wars and have been mined in locations ensuring fair pay, safe working conditions, enviromentally sound practices, and no human rights abuses.

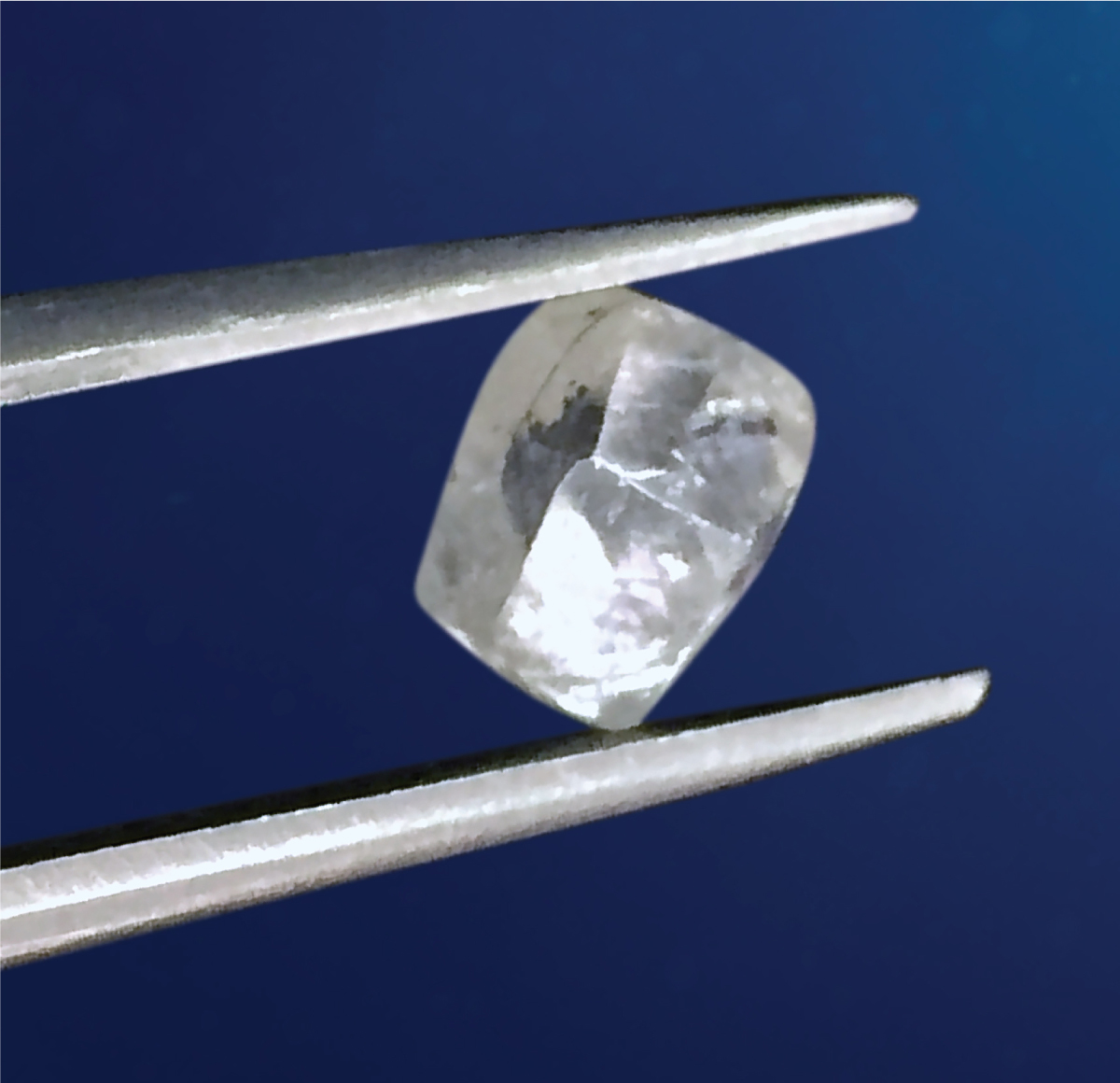

Rough Diamond Crystal Selection

The first step in our process is the acquisition of rough diamonds to send to our factories. We have long-term relationships with reputable sources. Upon purchase, we receive documentation that these crystals have passed through the Kimberly process. This states the country of origin and importantly that it is from a conflict free source.

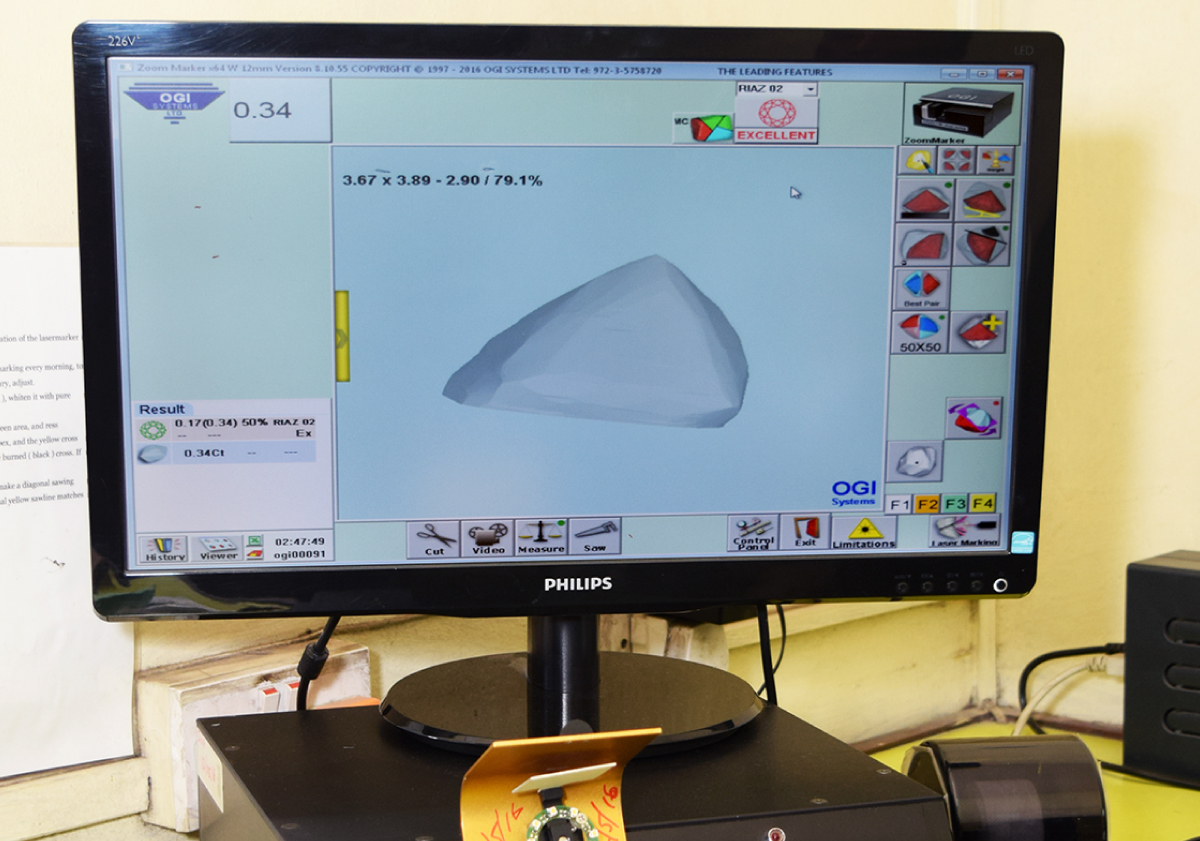

Mapping and Plotting

Each rough crystal is then scanned and marked using a machine. This allows us to maximize each diamond’s potential, keep weight loss at a minimum, and cut to ideal cut proportions.

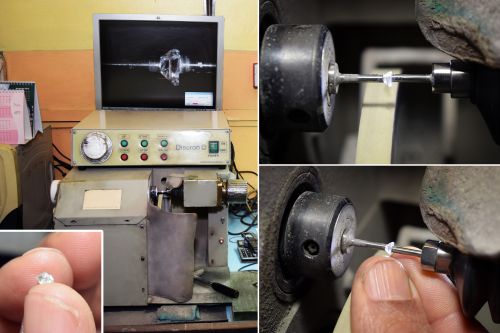

Bruting and Girdling

Once it is decided how the diamond crystal should be cut, it is mounted on the end of a dop stick. It is sawed at specific points to yield the greatest value. The following step in cutting a round stone is called bruting or girdling. At this point, the thin edge is being created on the diamond that separates the top (crown) from the bottom (pavilion). The diamond to be girdled is placed in the chuck of a lathe; while it spins and is shaped by another diamond or a diamond impregnated wheel.

Polishing

Once the basic shape has been established, the difficult task of placing the facets on the diamond. Great skill is necessary at every step of the cutting process, but especially during faceting. This is the human contribution and can elevate the value significantly. Following exact angles and perfect symmetry will bring maximum dispersion (spectral colors) and scintillation (symmetrical white flashes) to the viewer.

Inspection

After polishing, the diamonds are reviewed in detail for quality and are sorted into their respective color and clarity grades. We pride ourselves on our consistent grading. So much so that you can order a specific quality, years later make the same request knowing they certainly will match. As a final precaution, all of our diamonds are meticulously screened for any synthetic or simulants to insure they are completely natural.

Finished Product

No matter what color or clarity chosen for your jewelry, our Ideal Cuts are Simply More Beautiful. They explode with life, even when they are as small as grains of salt. You and your client will see the difference.